Maker, Hahl

Automatic Clock Co, Chicago, Illinois, USA. serial no. 318, made in 1913.

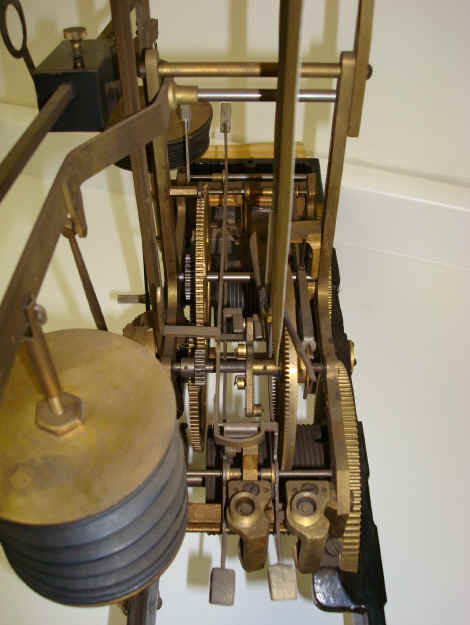

The photos below show the movement before restoration. Considering the state that these

movements are normally found in, especially the rubber bellows, this was in remarkable

condition. The rubber was in a perfect operable state after nearly 100 years!

The movement is a veritable Rube Goldberg device to see in action. Once per minute the

large vertical fly is released and all of the wheel works begin to turn, simultaneously

the pivoted balance tilts to one side, the minute hand advances and the spring remontoire

is wound 1/8 turn. Various levers are raised and released opening and closing the air

needle valves which are attached to the bellows which alternatively supply compression and

evacuation to the air lines.

The first photo below shows the one-minute spring remontoire and frictionless crutch

system. The grooved, pivoted plate when in place, is in a horizontal position. The

pendulum has a pivoted, sharp-edges wheel that rides in this groove. The second photo

shows the needle valves that supply the air that is alternately compressed and evacuated

thus pushing and then pulling a plunger in the slave to advance a ratchet wheel much like

an electric solenoid does in a conventional slave.

The two weight stacks together weigh 156lb and drive the two great wheels

simultaneously through a common pinion. A testament to the huge amount of energy that this

system requires for operation. Even large tower clocks do not require such weight for the

time train. The next photo shows one of a pair on manometers that verify the air lines are

air tight.